visual documentation

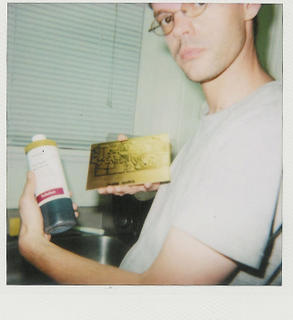

The procedure for etching a circuit board is roughly as follows:

-transfer your circuit design onto the board using any of the various means out there.

-dump the board into a tub of ferric chloride. This etches away the copper from the board that is *not* covered by the ink from your transfer.

-when fully etched, use Mystery Enclosed Cleaning Solution to wipe the ink off.

-neutralize the etch with cold water.

After the struggle with getting our design on the board free hand, we were ready to etch, using our newly purchased Pyrex pan as a tub for the ferric:

So we put in the board, agitated, stirred, waited, agitated, waited, waited...

After an hour or so (where the kit stated part should take us "twenty to thirty minutes", Ms S suggested we should head down to the Fleetwood Diner while we wait. One lovely greasy late breakfast later, we came back to find /some/ etching happening at the edges of the board, but certainly not a significant amount.

More agitating:

-transfer your circuit design onto the board using any of the various means out there.

-dump the board into a tub of ferric chloride. This etches away the copper from the board that is *not* covered by the ink from your transfer.

-when fully etched, use Mystery Enclosed Cleaning Solution to wipe the ink off.

-neutralize the etch with cold water.

After the struggle with getting our design on the board free hand, we were ready to etch, using our newly purchased Pyrex pan as a tub for the ferric:

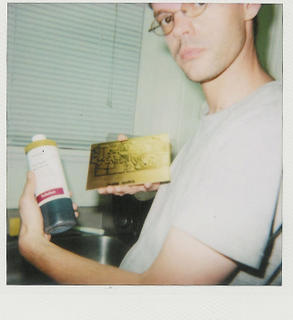

So we put in the board, agitated, stirred, waited, agitated, waited, waited...

After an hour or so (where the kit stated part should take us "twenty to thirty minutes", Ms S suggested we should head down to the Fleetwood Diner while we wait. One lovely greasy late breakfast later, we came back to find /some/ etching happening at the edges of the board, but certainly not a significant amount.

More agitating: